Mounting/Demounting

ATTENTION: If dizziness or incoordination are of concern or you are otherwise not up to the task, then DO NOT attempt to mount the equipment yourself. Some minimal athleticism required.

— For Audio-Visual Instruction, see: GALLERY videos —

How To Board Mount TheShootingstreak® Personal Trainer

To mount, you may need to use a stepladder or if adjustable, simply lower the backboard goal assembly and hang the Support Assembly (SA) on the backboard and then the Trough Assembly (TA) on the SA. To demount, just reverse the aforementioned procedure that is meticulously described next, in concisely abbreviated text, below:

1. Situate the stepladder so that it's centered beneath the basketball hoop. Configure the Support Assembly as follows: Firstly, (A) Customize the paired Inverted J-Hook mounting pins' position as needed to adjust for backboard thickness (See: Information: 'Detail Photos': a1). Secondly, (B) Customize the paired Spring Clip Buttons' position as needed to adjust for backboard height ('Detail Photos': a2).

2. Carry the Support Assembly (SA) and step up[ward] as needed. Hoist and position SA so that its Vertical Arms straddle basketball hoop with Assembly Crossbar running laterally beneath the hoop. Lift SA so both mounting pins situated atop Upper Vertical Arms clear backboard location ("x") ('Detail Photos': a1).

3. Lower Support Assembly so that it mounts, centered, atop and against face of backboard, and straddling the hoop (See near page bottom: MOUNTING ORIENTATION). Stop and briefly inspect its position. If not centered under hoop, adjust by slightly lifting and and lowering SA into a more centered position. (Normally, it's not necessary to dismount Trough Assembly first.) Next, take hold of Trough Assembly (TA).

4. Refold Trough Assembly (TA) by rotating the two uppermost panel wires together so that they converge to form an alpine "A" shape and then, with the left and right panel tops essentially touching each other and the panel bottom runway tubes running parallel to each other, place TA down on the ground ('Detail Photos': b, c).

5. Relocate stepladder so that it is centered (for a person of right hand dominance) in comfortable vertical alignment with left vertical arm of Support Assembly. Pick up A-shaped TA (with hooks pointing toward the SA) by grasping the two panel top wires together with the right hand, and, taking care to balance weight of Trough Assembly, return to your original position on stepladder while still holding "A" shape of TA.

— ALWAYS CARRY THE TROUGH ASSEMBLY FROM ITS CENTRAL BALANCE POINT —

6. Place Trough Assembly into position by raising it up (taking care to firstly guide Rear Anchor up within Catch Plate) and then lowering it at middle of Crossbar such that the two adjacent hook ends both hook themselves over top edge of Crossbar ('Detail Photos': d). Allow weight of TA to transfer entirely to SA. By carefully letting go of TA at this point, Rear Anchor of TA is allowed to safely come to rest against Catch Plate at bottom rung of SA.

7. Finally, with right and left hand each grasping its own respective side of the Trough Assembly (i.e., right or left panel), by briskly pushing with the right hand and pulling with the left, brusquely slide panels apart until their hook ends descend into their respective Crossbar slots and drop to their final resting positions at slot bottoms ('Detail Photos': e). This abrupt mechanical action should result in Rear Anchor being captured by and seating itself automatically against Catch Plate at bottom rung of SA. Make certain both panel hooks are securely in place at slot bottoms with Rear Anchor of TA coming to rest by its own weight against Catch Plate of SA.

Always be sure to inspect configuration of apparatus before using it. After a few practice trials, you’ll notice yourself getting it configured normally right away. Then you'll be mounting it in de minimis time. (Estimated time: <1 minute.)

— WHEN REMOVING STEPLADDER TO COURTSIDE, TAKE CARE TO PLACE IT SAFELY OUT OF HARM’S WAY —

Basic Mounting Configuration Checkpoints:

• TheShootingstreak® PT should be secure atop backboard with its mounting pins inserted correctly to fit the specific dimensions of the backboard presently in use. The gap maintained by mounting pins should afford clearance larger than the thickness of the backboard upon which apparatus is being mounted.

Although there may be no need to alter the gap the pins create, especially when used with same (i.e., size thickness) backboard, yet it is always prudent to check that they are located (per Inverted J-Hook design faculty) securely in place and are in detente position, unable to rotate or to move backward when under backward directional force.

— SECURE EACH MOUNTING PIN IN PLACE. TEST THAT EACH CAP NUT IS FULLY TIGHTENED —

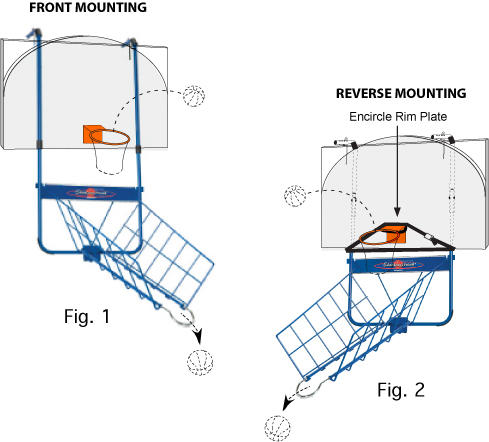

• TheShootingstreak® PT should be adjusted to a favorable height in relation to the specific vertical dimensions of the backboard presently in use. There are four sizes of conventional backboards. Determine whether your backboard is short, medium, long, or extra long in its vertical dimension and adjust height of Support Assembly accordingly. Check to see that, when mounted, Trough Assembly is situated with basketball net hanging comfortably down above Trough. (Crossbar of Trough Assembly can be selectively positioned at optional distances below backboard, i.e., selectively positioned closer to either player [convenience] or goal [reinforcement] (Compare: Fig. 1 and Fig. 2, below).

• TheShootingstreak® PT should be centered about hoop so that the ball will be collected properly.

MOUNTING ORIENTATION: Figures 1 & 2

Premium Reverse Mounting Position*: Behind the Backboard (Wrap Strap to span over Rim Plate) — *System(s)/Ball Baffle† Prerequisite —

Alternatively, for unobstructed angular shots off the backboard, Support Assembly can be positioned on backside of backboard (See: Figure 2, above). The procedure for reverse mounting is basically the same as that for front mounting except that Upper Arms are rotated 180° and locked into position with detente buttons. When lowered to rest atop backboard, the Inverted J-Hook mounting pins come to rest on front side of board, with the tubes running down the backside (instead of front). To pull lower part of Support Assembly snugly against bottom of backboard, it can be cinched into correct position using a polypropylene strap which passes behind arms of Support Assembly and forms a loop which can pass about (so as to wrap around) and ultimately span over rim of basket, specifically, encircling either support wires beneath and/or spanning over horizontal plate of rim where it projects itself away from backboard. Such a strap should be generally 6 feet long and, also, at least 1" wide with an adjustable (length) safety buckle. (Most hardware stores carry an affordable carrying tie of this type: e.g., B.S.R. 1-A acculoc made by ACW, Woonsocket, R.I.).

Optionally, for those ordering in a timely way while product is in stock, there is the recommended convenience that, this item, with purchase of any System or SystemPLUS product, automatically ships as a specifically customized strap (set) consolidated in the box (i.e., cinch strap free shipping). Moreover, our specifically customized strap set (made in the USA by California Webbing Mills, Los Angeles, CA) can be chosen separately as a particular item with its own shipping fee and added to customer shopping cart.

The †SideShield™ Ball Baffle information page shows a graphic view of our customized strap set configuration. Note that instead of an unattached, single piece, strap required to be held and placed to pass behind the lower arms of Support Assembly (See: Fig. 2, above), our customized Sgsk Reverse Mounting Strap [Set] is comprised of two pieces, the loop end of each piece being easily slipped on (only once) to attach to a lower arm (Right or Left) of Support Assembly U-Frame, and, once ready, the longer length is placed to span over the rim plate and the other [shorter] length is extended up to meet the longer one and the two straps then are buckled together.

IN TRANSPORTING (Folded Flat): Check that both Support Assembly Upper Vertical Arms' mounting pins are inserted into their thru-holes and appropriately secured with cap nuts for captivity. Also check that Sidekicker™ Side Shot Deflectors are captured congruently on Trainer's Track Extender tubes and pressed on tight for transport (or pocketed and carried along separately).

- FAQs

- Specifications

- Detail Photos

- SideShield™ Ball Baffle

- PracticeARC™ Archway

- Sidekicker™ Deflectors

- Mounting/Demounting

- Scientific Rationale

- Institutional Interests: Family Values

- Institutional Interests: Schools

- Institutional Interests: Parks

- Institutional Interests: Camps

- Institutional Interests: Community Centers

- Privacy Policy

- Terms & Conditions

- Warranty & Returns

- SGSKSystems Trainer Certification

- ShowTime Training Scorecard

- Credits

- Contact Us

Copyright © 2025 Shootingstreak Enterprises. All Rights Reserved.